Sie sind während Ihres Projektes auf ein Problem gestoßen und sollen dieses schnellstmöglich lösen? Wir stellen Ihnen heute eine Methode des Lean Managements vor, die Sie clever zum Ziel führt: Das Ishikawa Diagramm. Es handelt sich hierbei um eine grafische Darstellung aller Problemursachen und ihrer Abhängigkeiten zueinander. Die Methode wurde in den 1940er Jahren vom japanischen Wissenschaftler Kaoru Ishikawa entwickelt und trägt zum besseren Verständnis von Ursachen und deren Wirkung bei.

Bei der Visualisierung eines Problemlösungsprozesses wird analytisch nach den Ursachen eines derzeit bestehenden Problems gesucht. Die Hauptursachen werden dabei solange zerlegt, bis die Wurzel des Problems erreicht wurde. Die Methode eignet sich besonders für die Zusammenarbeit in Gruppen und kann als Brainstorming-Session durchgeführt werden.

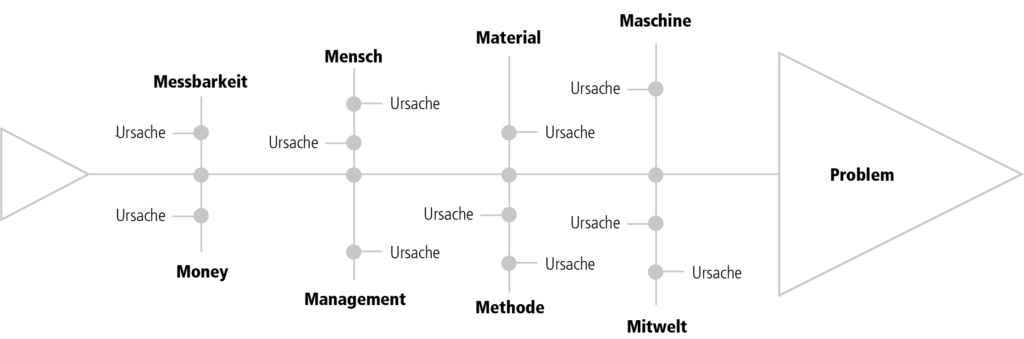

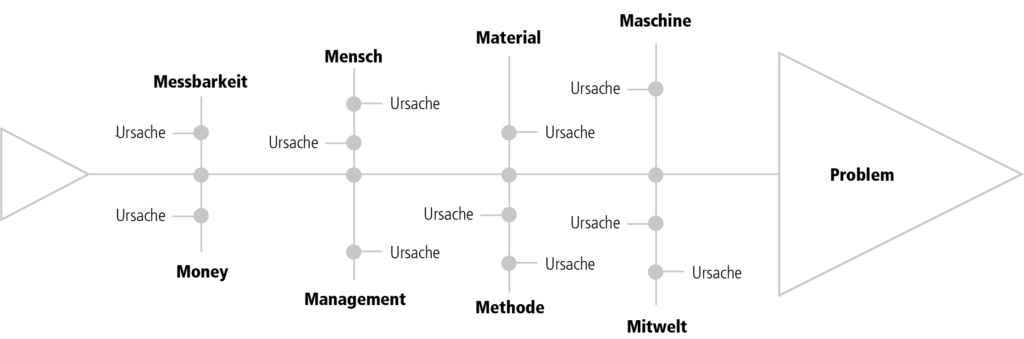

Die grafische Darstellung des Ishikawa Diagramms ähnelt einem Fisch mit seinen Gräten. Ausgangspunkt ist ein horizontaler Pfeil nach rechts, an dessen Spitze (dem Kopf des Fisches) das möglichst treffend formulierte Problem steht. An den quer verlaufenden Hauptzweigen (den Gräten) befinden sich die Ursachen. Zur Orientierung werden einige Kategorien nach der 8M-Methode vorgegeben:

Mensch, Material, Maschine, Methode, Mitwelt, Management, Messbarkeit, Money

Diese Kategorien sind lediglich als Vorschläge zu betrachten. Legen Sie den Fokus auf Ihr spezifisches Problem und passen Sie die Kategorien der Hauptzweige – wenn nötig – daran an.

An jedem Hauptzweig werden so möglichst konkrete Ursachen notiert, die auch weiter verzweigt werden können. In der Regel muss eine Ursache mehrmals hinterfragt werden, um an die Wurzel des Problems zu stoßen. Sind die Wurzeln nämlich erst einmal gefunden, so können sie zielgerichtet angepackt werden.

Innerhalb der gemeinsam identifizierten, möglichen Ursachen wird nun priorisiert.

Welche Ursachen sind wahrscheinlich konkret für das Problem verantwortlich? Welche sind gegebenenfalls eher nebensächlich? In diesem Schritt wird die Hauptursache festgesetzt – in Ausnahmefällen können auch mehrere Hauptursachen herausgefiltert werden.

In der abschließenden Phase ist es essenziell, die ausgewählten Hauptursachen für eine spezifische Ableitungen von Handlungsoptionen und Vorgehensweisen zu nutzen, um das Problem in Zukunft tatsächlich zu eliminieren. Schieben Sie diesen Schritt nicht auf! Es besteht die Gefahr, die eigentliche Lösung des Problems aus den Augen zu verlieren.

Das Prinzip Lean Management ist eine ganzheitliche Verfahrensweise, um mithilfe unterschiedlicher Methoden die gesamte Wertschöpfungskette eines Unternehmens effizient zu gestalten. Prozesse werden optimal aufeinander abgestimmt und überflüssige Tätigkeiten vermieden. Das Ishikawa Diagramm und viele weitere, nützliche Methoden sind Bestandteil unserer neuen Online Qualifizierung. Das Format bietet Ihnen außerdem die Flexibilität, die Sie in der aktuellen Zeit brauchen: Nehmen Sie entspannt von Zuhause an den Online-Sessions teil! Der nächste Start des Programms ist im März 2021.